Main Applications

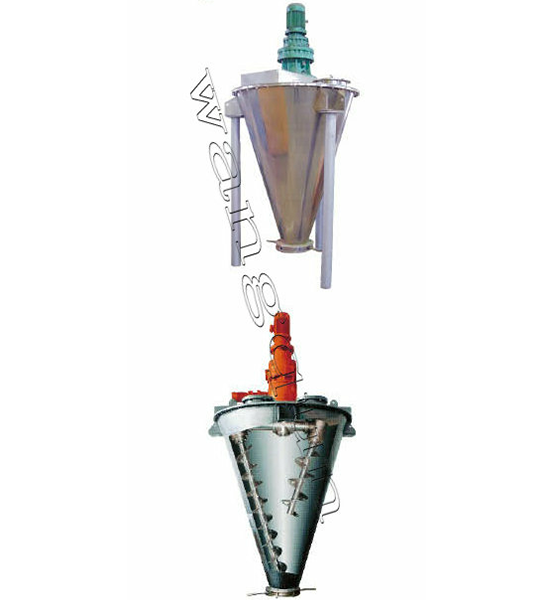

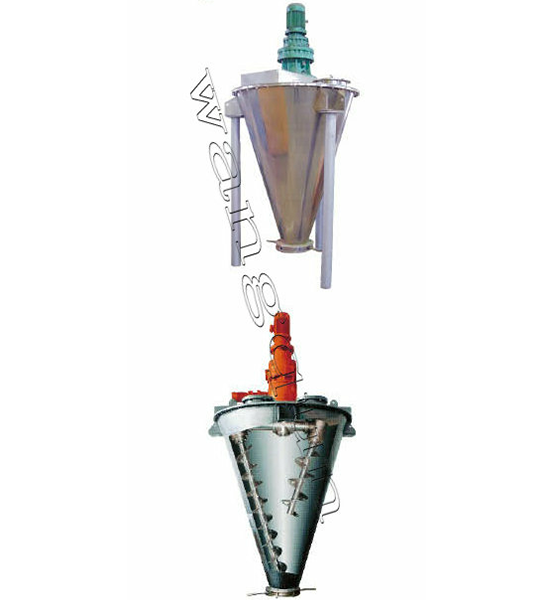

SHJ twin-screw conical mixer is a type of conical mixer with a large application area for powder and granular mixing . It is a new type of high-efficiency and high-precision mixing equipment, widely used in mixing powder (granular) materials such as chemicals, pesticides, and feed, and is particularly suitable for mixing materials with large differences in specific gravity and mixing ratio.

Features

It has strong adaptability to materials with different specific gravities and particle sizes;

Gentle mixing, no crushing or grinding of granular materials, no overheating of heat-sensitive materials;

It can not only mix powders and granules, but also add a small amount of liquid for mixing;

The mixing speed is fast and the mixing time is short;

High mixing uniformity, generally the mixing uniformity variation coefficient is ≤5% ;

There is no dead angle in mixing, and the discharge is fast and clean;

Changing some structures of the machine can produce some new functions;

It has good compatibility. Adding some supporting devices can make the operation more convenient and the use more satisfactory.

It is easy to install and operate, easy to clean and maintain, and has a long service life.

Technical Parameters

model | SHJ-200 | SHJ-500 | SHJ-1000 | SHJ-2000 | SHJ-3000 | SHJ-4000 | SHJ-10000 | SHJ-40000 |

Total volume (m2) | 0.2 | 0.5 | 1 | 2 | 3 | 4 | 10 | 15 |

Loading factor | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Maximum loading weight (kg) | 95 | 190 | 380 | 720 | 1080 | 1400 | 3600 | 5400 |

loose density | -0.8 | -0.8 | -0.8 | -0.8 | -0.8 | -0.8 | -0.8 | -0.8 |

Material particle size (mesh) | 20-250 | 20-250 | 20-250 | 20-250 | 20-250 | 20-250 | 20-250 | 20-250 |

Power (kw) | 2.2 | 2.2 | 4 | 5.5 | 7.5 | 11 | 18.5 | twenty two |

Mixing time (min) | 6-10 | 6-10 | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

Overall dimensions (mm) | Φ900*1905 | Φ1160*2215 | Φ1450*2820 | Φ1850*3450 | Φ2050*3780 | Φ2260*4210 | Φ3080*5810 | Φ3576*6310 |

Weight (kg) | 500 | 600 | 1300 | 1600 | 2500 | 2800 | 5600 | 6700 |

Twin-screw Conical Mixer: Advanced Industrial Mixing Solutions

Introduction

The Twin-screw Conical Mixer is a cutting-edge industrial machine designed for efficient and uniform blending of powders, granules, and other bulk materials. Its dual-screw conical design ensures thorough mixing while minimizing material degradation, dust generation, and energy consumption. Widely used in pharmaceutical, chemical, food, nutraceutical, and feed industries, this mixer delivers high-performance blending for both laboratory-scale and industrial-scale production. The mixer’s robust construction, user-friendly controls, and adjustable operating parameters make it a reliable solution for modern manufacturing processes.

Technical Features and Advantages

Uniform and Efficient Mixing

The twin-screw conical design ensures continuous movement of materials from the narrow bottom to the wide top of the cone, achieving homogeneous blending.

Reduces dead zones and prevents segregation of particles of different sizes and densities.

Suitable for sensitive materials where gentle mixing is required.

Energy Efficiency

Optimized screw rotation minimizes energy consumption while maintaining high mixing performance.

Reduced operational time compared to traditional mixers.

Supports eco-friendly production standards with low heat generation.

Durability and Construction

Stainless steel body and screws provide corrosion resistance and long-term durability.

Smooth internal surfaces prevent material adhesion and facilitate cleaning.

Wear-resistant coatings extend component life in high-volume production.

Operational Flexibility

Adjustable screw speed and rotation direction for different materials.

Compatible with dry powders, granules, tablets, and sensitive chemical compounds.

Easy integration into production lines or standalone operations.

Technical Parameters

| Parameter | Typical Range | Description |

|---|

| Mixing Capacity | 50–2000 kg/batch | Depending on model size |

| Screw Rotation Speed | 10–60 rpm | Adjustable for optimal mixing |

| Motor Power | 1–15 kW | Ensures stable performance |

| Cone Angle | 30–60° | Facilitates material movement |

| Material | Stainless steel (SS304/SS316) | Corrosion-resistant, easy to clean |

| Batch Cycle Time | 10–60 minutes | Adjustable based on material type |

| Dimensions | Customized | Based on production capacity |

| Control System | Manual or PLC | Easy operation and monitoring |

Applications and Scope

Pharmaceutical Industry

Blending medicinal powders, granules, and excipients.

Preparing uniform mixtures for tablet pressing, capsule filling, and coating processes.

Ensures precise dosage and consistent product quality.

Chemical Industry

Mixing chemical powders, catalysts, and pigments.

Prevents particle segregation and improves reaction uniformity.

Suitable for corrosive and sensitive chemicals.

Food and Nutraceutical Industry

Blending spices, herbal powders, vitamins, and food additives.

Ensures consistent taste, color, and nutritional content.

Minimizes dust and prevents cross-contamination.

Feed and Agriculture

Mixing animal feed, premixes, and grains.

Uniform distribution of nutrients, supplements, and additives.

Supports high-volume production with consistent quality.

| Industry | Typical Materials | Key Benefits |

|---|

| Pharmaceutical | Powders, excipients | Uniform dosage, smooth tablet pressing |

| Chemical | Catalysts, pigments | Homogeneous chemical reactions |

| Food & Nutraceutical | Spices, herbal powders | Consistent taste, color, nutrient distribution |

| Feed & Agriculture | Grains, premixes | Balanced nutrition, high throughput |

Fault Diagnosis and Maintenance

Common Issues

Uneven Mixing

Cause: Incorrect screw speed, overload, or material segregation

Solution: Adjust screw speed, reduce batch size, ensure proper loading

Motor Overheating

Cause: Prolonged operation or insufficient ventilation

Solution: Allow cooling periods, check motor ventilation, reduce load

Excessive Vibration or Noise

Cause: Loose screws, misaligned components, or worn bearings

Solution: Tighten screws, realign mixer, replace bearings

Material Adhesion

Cause: Sticky powders or insufficient cleaning

Solution: Regular cleaning, use non-stick coatings, adjust mixing time

Preventive Maintenance

Clean the mixer after each batch to avoid contamination.

Inspect screws, bearings, and motor regularly.

Lubricate mechanical components as recommended by the manufacturer.

Verify electrical connections and safety devices before each operation.

| Issue | Possible Cause | Recommended Action |

|---|

| Uneven Mixing | Wrong speed, overload | Adjust speed, reduce batch size |

| Motor Overheating | Continuous use | Allow cooling, check ventilation |

| Vibration/Noise | Loose parts, worn bearings | Tighten, realign, replace |

| Material Adhesion | Sticky powders | Clean, adjust mixing time, non-stick coating |

Operation Guidelines

Preparation: Ensure the mixer is clean and all screws and components are properly installed.

Loading Material: Fill the mixer according to batch capacity; avoid overloading.

Parameter Setting: Set the appropriate screw speed, rotation direction, and mixing time.

Mixing Process: Start the mixer, monitor operation, and observe material flow.

Discharge: Open the bottom outlet, collect mixed materials, and check uniformity.

Cleaning: Clean the mixer thoroughly before the next batch to prevent contamination.

Conclusion

The Twin-screw Conical Mixer offers high-efficiency, uniform mixing for a wide range of industrial applications, including pharmaceuticals, chemicals, food, nutraceuticals, and animal feed. Its robust construction, energy efficiency, and versatile operation make it an essential component of modern production lines. Regular maintenance, fault diagnosis, and proper operation ensure long-term reliability and optimal performance. With adjustable settings, precise control, and easy integration, this mixer helps manufacturers achieve consistent product quality, reduced production time, and improved operational efficiency.

Investing in a Twin-screw Conical Mixer guarantees enhanced mixing performance, safer operation, and high-quality output, making it ideal for laboratory and industrial production environments.

Phone

Phone