Reasons to choose us:

1. Strong technical force, advanced equipment, all product indicators meet national standards, reliable product quality and stable performance.

2. Worry-free after-sales service, customer first, providing warm and attentive service.

Service philosophy:

Competition makes the market economy highly dynamic. We are committed to providing excellent service. Only in this way can we survive and stand out in this highly competitive market, because we believe that the key to our development lies in developing customers.

We favor mutual trust and respect, and therefore focus on establishing broad and equal cooperative relationships with customers, as well as strategic partnerships. At the same time, we also strive to explore and manage our customers' interests and needs. At our company, the concept of "customer first" is widely accepted. We adjust our product portfolio according to market changes and new customer needs, investing in research and innovation at all times. Establishing and completing customer service is always a priority.

Tablet Press Worm: Comprehensive Guide for Specifications, Maintenance, and Repair

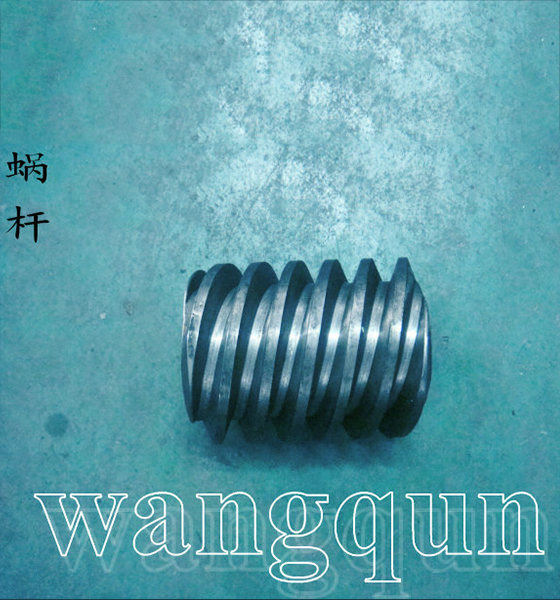

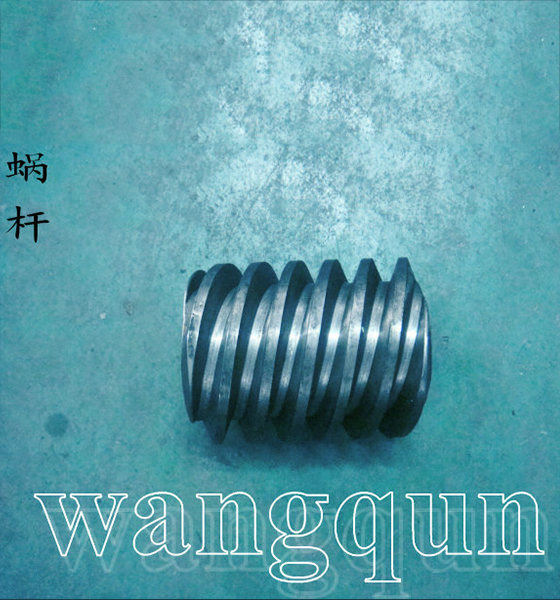

Introduction to Tablet Press Worm

A Tablet Press Worm is a critical mechanical component in Pharmaceutical tablet presses, ensuring precise torque transmission, smooth rotation, and consistent compression of tablet material. It is typically paired with a worm gear and rotating table, forming a key transmission system that guarantees uniform tablet size, weight, and density.

Constructed from high-strength alloy steel or wear-resistant bronze, the tablet press worm offers long service life, low noise, and high durability under continuous operation. Proper installation, maintenance, and usage are crucial to optimize performance and extend the life of the machine.

Key Features of Tablet Press Worm

High Precision – ensures accurate alignment and consistent tablet production.

Durable Construction – resistant to wear, corrosion, and heavy loads.

Smooth Operation – reduces vibration and mechanical noise.

Easy Maintenance – designed for straightforward cleaning and lubrication.

Wide Compatibility – fits multiple models of Tablet press machines.

Product Specifications

Below is a typical tablet press worm specification table (values may vary by manufacturer and model):

| Parameter | Specification | Notes |

|---|

| Material | Alloy Steel / Bronze | Heat-treated for durability |

| Hardness | 45–60 HRC | Ensures wear resistance |

| Length | 150–300 mm | Depending on tablet press model |

| Diameter | 20–50 mm | Shaft diameter |

| Pitch | 2–5 mm | Matches corresponding worm gear |

| Load Capacity | Up to 500 Nm | Continuous operation |

| Surface Finish | Ra ≤ 1.6 μm | Smooth gear engagement |

These parameters ensure consistent torque transmission, proper alignment with the worm gear, and reliable operation in high-speed tablet production.

Installation Guidelines

Step 1: Preparation

Verify the worm matches the tablet press model.

Clean the worm shaft, gear, and mounting area to remove dust, grease, or debris.

Gather necessary tools: torque wrench, alignment gauge, and lubricant.

Step 2: Positioning

Step 3: Securing

Step 4: Lubrication

Step 5: Testing

Rotate the worm manually to ensure smooth movement.

Start the tablet press at low speed, then gradually increase to normal operating speed.

Maintenance Requirements

Proper maintenance is essential to prolong worm life and ensure consistent tablet quality.

Daily Maintenance

Check for abnormal noise, vibration, or heat.

Ensure lubrication levels are sufficient.

Weekly Maintenance

Monthly Maintenance

Annual Maintenance

Conduct a full inspection of worm, gear, bearings, and housing.

Replace worn or damaged components.

Recalibrate the worm for optimal engagement with the worm gear.

Usage Precautions

To ensure safe and efficient operation:

Do not exceed load limits – overloading may cause premature wear or breakage.

Maintain proper lubrication – lack of lubrication leads to overheating and gear damage.

Check alignment regularly – misalignment increases friction and reduces production quality.

Avoid contamination – keep the worm free from dust, chemicals, and moisture.

Use genuine replacement parts – non-standard components may affect performance.

Troubleshooting and Repair Process

Even with proper maintenance, occasional issues may arise.

| Problem | Possible Cause | Solution |

|---|

| Tablet press worm rotates unevenly | Misalignment with worm gear | Realign worm and gear, check shaft |

| Excessive noise during operation | Worn threads or inadequate lubrication | Apply lubrication, replace worn worm |

| Overheating | High load or continuous operation | Reduce load, improve cooling, check lubrication |

| Vibration or shaking | Loose mounting bolts | Tighten bolts and check alignment |

Repair Workflow

Power off the machine and disconnect the electrical supply.

Remove the worm carefully following manufacturer instructions.

Inspect for wear, cracks, or deformation.

Clean or replace worn parts as needed.

Reinstall the worm and perform alignment and torque checks.

Apply lubrication, run a test cycle, and verify smooth operation.

Advantages of Tablet Press Worm

Ensures consistent tablet weight and thickness.

Reduces mechanical noise and vibration.

Provides long service life with minimal maintenance.

Supports high-speed and high-volume tablet production.

Compatible with multiple pharmaceutical, food, and chemical tablet presses.

Conclusion

The Tablet Press Worm is an essential component for achieving precision, efficiency, and reliability in pharmaceutical tablet production. Following proper installation, maintenance, usage precautions, and repair procedures ensures long-term performance and minimizes downtime.

Investing in high-quality, durable tablet press worms allows manufacturers to maintain consistent tablet quality, reduce operational costs, and optimize production efficiency.

Phone

Phone