Reasons to choose us:

1. Strong technical force, advanced equipment, all product indicators meet national standards, reliable product quality and stable performance.

2. Worry-free after-sales service, customer first, providing warm and attentive service.

Service philosophy:

Competition makes the market economy highly dynamic. We are committed to providing excellent service. Only in this way can we survive and stand out in this highly competitive market, because we believe that the key to our development lies in developing customers.

We favor mutual trust and respect, and therefore focus on establishing broad and equal cooperative relationships with customers, as well as strategic partnerships. At the same time, we also strive to explore and manage our customers' interests and needs. At our company, the concept of "customer first" is widely accepted. We adjust our product portfolio according to market changes and new customer needs, investing in research and innovation at all times. Establishing and completing customer service is always a priority.

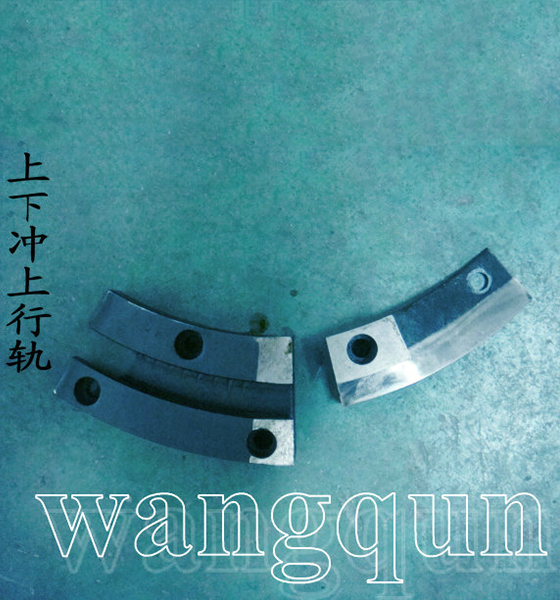

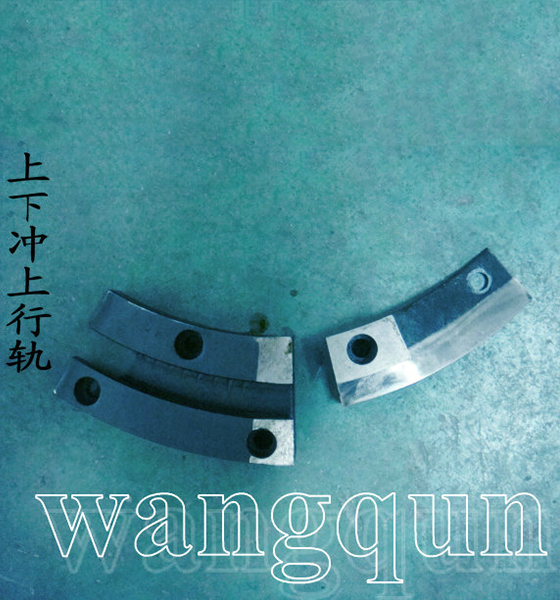

Tablet Press Lower Punch Up and Down Rails: Installation, Advantages, and Operational Guide

Introduction to Tablet Press Lower Punch Rails

The Tablet Press Lower Punch Up and Down Rails are critical precision components in pharmaceutical Tablet press machines. They guide the lower punches during the compression process, ensuring smooth vertical movement, accurate alignment, and consistent tablet thickness.

Constructed from high-strength, wear-resistant steel or alloy, these rails provide long-lasting durability and reliability, minimizing mechanical wear and vibration. Their design supports high-speed, high-efficiency tablet production, making them indispensable in pharmaceutical, chemical, and food industries.

Core Advantages

Precision Guidance – Ensures accurate vertical movement of lower punches for uniform tablet size and weight.

Durable Construction – High-strength steel or alloy resists wear, reducing replacement frequency.

Operational Reliability – Minimizes vibration and mechanical stress during high-speed tablet pressing.

Easy Maintenance – Smooth surfaces allow easy inspection and cleaning.

Compatibility – Designed to fit multiple tablet press models seamlessly.

Energy Efficiency – Optimized design reduces friction and machine energy consumption.

Installation Guide

Proper installation of the lower punch rails is essential for safe and efficient operation.

Step 1: Pre-Installation Checks

Inspect rails for visible damage, corrosion, or deformation.

Verify dimensions and compatibility with the tablet press model.

Ensure all mounting hardware is available and in good condition.

Step 2: Positioning the Rails

Step 3: Securing the Rails

Step 4: Operational Test

Product Specification Table

| Parameter | Specification | Notes |

|---|

| Material | High-strength steel / Alloy | Wear-resistant and durable |

| Length | 200–500 mm | Adjustable for machine model |

| Width | 20–50 mm | Ensures proper punch alignment |

| Surface Finish | Polished / Ground | Minimizes friction |

| Load Capacity | 50–150 kg | Depends on tablet press type |

| Operating Temperature | 5–40°C | Avoid extreme temperatures |

| Compatibility | Multiple tablet press models | Ensure correct alignment |

Energy Efficiency Standards

Optimizing tablet press operations with high-quality rails can reduce energy consumption and operational costs:

Low Friction Surface: Polished rails decrease resistance, lowering motor load.

Durable Construction: Reduces frequent replacements, minimizing material and energy usage.

Precision Alignment: Prevents unnecessary power draw due to punch misalignment.

Maintenance Efficiency: Simplified cleaning reduces downtime and energy usage during operations.

Compliance with ISO 50001 energy management standards can be supported by using optimized rails in tablet press systems.

Operational Procedures

Daily Operation

During Production

Monitor tablet weight, thickness, and uniformity regularly.

Observe machine sounds for unusual friction or vibration.

Avoid exceeding recommended pressing speed and material load.

Post-Operation

Disconnect the machine from power before cleaning or adjusting rails.

Clean rails with approved agents to remove powder residue.

Inspect for wear or deformation and perform adjustments if necessary.

Maintenance Recommendations

Weekly Maintenance

Wipe rails with a clean, dry cloth to remove dust and powder.

Check mounting bolts and tighten as required.

Monthly Maintenance

Inspect surface for scratches, wear, or corrosion.

Apply a light machine-compatible lubricant if recommended.

Annual Maintenance

Core Advantages for Industrial Use

Precision and Reliability: Maintains accurate tablet thickness and weight.

Durability: High-strength materials reduce maintenance and downtime.

Operational Efficiency: Smooth punch movement decreases machine energy consumption.

Hygienic and Safe: Easy to clean, suitable for pharmaceutical production.

Versatile Compatibility: Fits multiple tablet press models and industrial environments.

Conclusion

The Tablet Press Lower Punch Up and Down Rails are vital for safe, efficient, and precise tablet production. With durable construction, precise guidance, and optimized energy efficiency, these rails help manufacturers achieve consistent tablet quality, reduce downtime, and improve production efficiency.

Proper installation, maintenance, and operational procedures are key to maximizing the lifespan and performance of the rails. By investing in high-quality, precision-engineered rails, pharmaceutical and food tablet manufacturers can ensure long-term operational reliability and productivity.

Phone

Phone