Reasons to choose us:

1. Strong technical force, advanced equipment, all product indicators meet national standards, reliable product quality and stable performance.

2. Worry-free after-sales service, customer first, providing warm and attentive service.

Service philosophy:

Competition makes the market economy highly dynamic. We are committed to providing excellent service. Only in this way can we survive and stand out in this highly competitive market, because we believe that the key to our development lies in developing customers.

We favor mutual trust and respect, and therefore focus on establishing broad and equal cooperative relationships with customers, as well as strategic partnerships. At the same time, we also strive to explore and manage our customers' interests and needs. At our company, the concept of "customer first" is widely accepted. We adjust our product portfolio according to market changes and new customer needs, investing in research and innovation at all times. Establishing and completing customer service is always a priority.

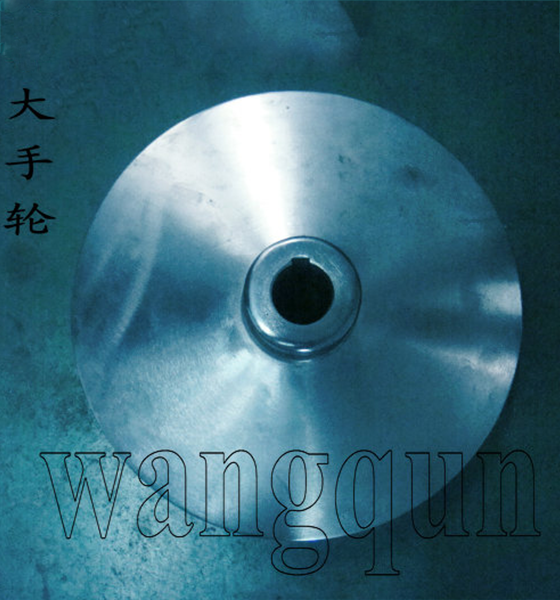

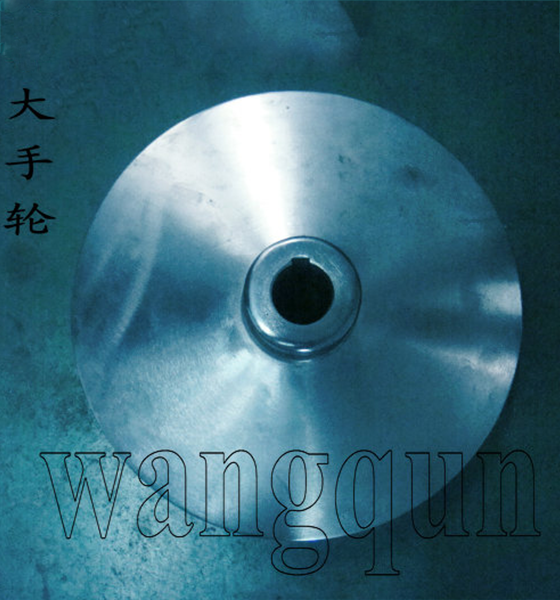

Tablet Press Large Handwheel: Safety, Maintenance, and Operational Guide

Introduction

The Tablet Press Large Handwheel is a critical manual control component in Tablet press machines. It enables operators to precisely adjust compression force, tablet thickness, and die alignment, ensuring consistent tablet quality. Made from durable, corrosion-resistant materials, the handwheel is designed for smooth operation, ergonomic handling, and long-lasting performance.

Proper usage, adherence to safety protocols, and a structured maintenance plan are essential for maximizing the lifespan and efficiency of the handwheel while maintaining safe and reliable tablet production.

Core Advantages

Ergonomic Design – Reduces operator fatigue and enables precise control.

Durable Materials – High-strength alloys and corrosion-resistant coatings extend service life.

Smooth Rotation – Ensures consistent adjustments without slippage or binding.

Enhanced Safety – Designed to prevent accidental over-adjustment or operator injury.

Versatile Compatibility – Suitable for various tablet press models.

Safety Operation Procedures

Pre-Operation Checks

Inspect the handwheel for visible damage, cracks, or corrosion.

Ensure that all mounting bolts and fasteners are secure.

Verify that the machine is powered off before making manual adjustments.

Operating Guidelines

Turn the handwheel slowly and steadily to adjust tablet thickness or compression force.

Avoid forcing the handwheel beyond its mechanical limits.

Keep hands and loose clothing away from moving parts during operation.

Use proper lighting and a stable platform to maintain operator safety.

Post-Operation Procedures

Ensure the handwheel is in a neutral or safe position after adjustment.

Lock the handwheel or secure the machine if it will be idle for extended periods.

Record adjustments in the maintenance or production log for traceability.

Safety Guidelines

Always wear protective gloves and follow PPE regulations when operating the handwheel.

Avoid contact with lubricants or powders on the handwheel to prevent slips.

Ensure the handwheel rotation does not interfere with other machine components.

Keep the working area clean and free of obstacles to prevent accidental injuries.

Maintenance Schedule

A structured maintenance plan helps maintain handwheel efficiency and extend service life.

| Maintenance Type | Frequency | Tasks |

|---|

| Visual Inspection | Daily | Check for cracks, corrosion, or debris |

| Lubrication | Weekly | Apply recommended lubricant to rotation points |

| Fastener Check | Weekly | Ensure all bolts and screws are tight |

| Functional Test | Monthly | Verify smooth rotation and precise adjustment |

| Deep Cleaning | Quarterly | Remove handwheel, clean thoroughly, inspect for wear |

| Component Replacement | As Needed | Replace worn or damaged parts to maintain performance |

Care and Handling Recommendations

Avoid Excessive Force: Manual over-tightening can damage the handwheel and machine components.

Keep Clean: Wipe the handwheel after each shift to remove powder residue and contaminants.

Lubricate Regularly: Apply light machine oil to maintain smooth rotation without over-lubricating.

Store Properly: If removed, store in a dry, clean environment to prevent corrosion.

Monitor Wear: Replace the handwheel if visible wear or cracks appear to avoid operational failure.

Troubleshooting Common Issues

| Issue | Possible Cause | Recommended Action |

|---|

| Stiff rotation | Lack of lubrication or debris buildup | Clean and lubricate rotation points |

| Handwheel wobbling | Loose mounting bolts or worn shaft | Tighten bolts, inspect shaft and replace if necessary |

| Corrosion | Exposure to moisture or cleaning chemicals | Clean, dry, and apply protective coating |

| Difficulty adjusting compression | Misalignment with die or machine components | Realign machine and verify proper handwheel installation |

Advantages for Industrial Users

Enhanced Production Control: Allows precise tablet thickness and compression adjustments.

Reduced Operator Fatigue: Ergonomic design ensures comfort during repetitive adjustments.

Durable and Reliable: Withstands daily use in high-volume tablet production.

Safety Compliance: Reduces the risk of operator injury and accidental over-adjustment.

Long-Term Cost Savings: Proper maintenance extends handwheel lifespan and reduces downtime.

Application Fields

The Tablet Press Large Handwheel is widely used across multiple industries:

Pharmaceutical Industry: For tablets requiring precise dosing and thickness control.

Chemical Industry: Handling chemical tablets where controlled compression is critical.

Food Industry: Nutritional and supplement tablets requiring consistent density.

Cosmetics Industry: Tablet-form cosmetics like facial or bath tablets.

Conclusion

The Tablet Press Large Handwheel is an essential component for safe, efficient, and precise tablet manufacturing. Its ergonomic design, durable materials, and smooth rotation provide operators with reliable control over tablet compression and machine adjustments.

Following proper safety procedures, routine maintenance, and care guidelines ensures long-lasting performance, reduces operational downtime, and enhances overall production efficiency. Ideal for pharmaceutical, chemical, food, and cosmetic tablet production, the handwheel is a key investment in quality, safety, and operational excellence.

Phone

Phone