Reasons to choose us:

1. Strong technical force, advanced equipment, all product indicators meet national standards, reliable product quality and stable performance.

2. Worry-free after-sales service, customer first, providing warm and attentive service.

Service philosophy:

Competition makes the market economy highly dynamic. We are committed to providing excellent service. Only in this way can we survive and stand out in this highly competitive market, because we believe that the key to our development lies in developing customers.

We favor mutual trust and respect, and therefore focus on establishing broad and equal cooperative relationships with customers, as well as strategic partnerships. At the same time, we also strive to explore and manage our customers' interests and needs. At our company, the concept of "customer first" is widely accepted. We adjust our product portfolio according to market changes and new customer needs, investing in research and innovation at all times. Establishing and completing customer service is always a priority.

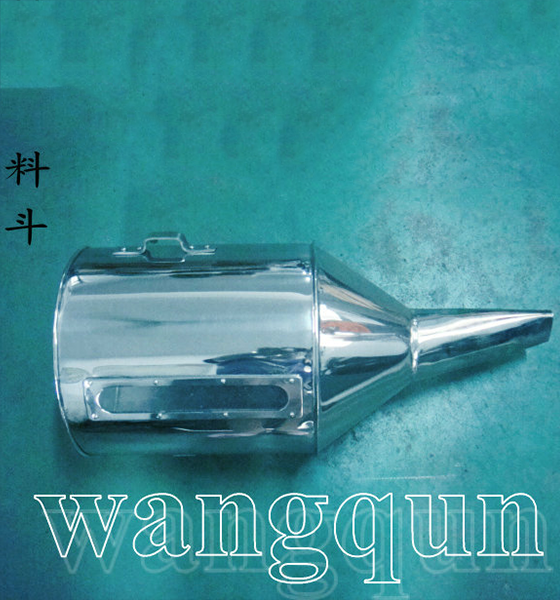

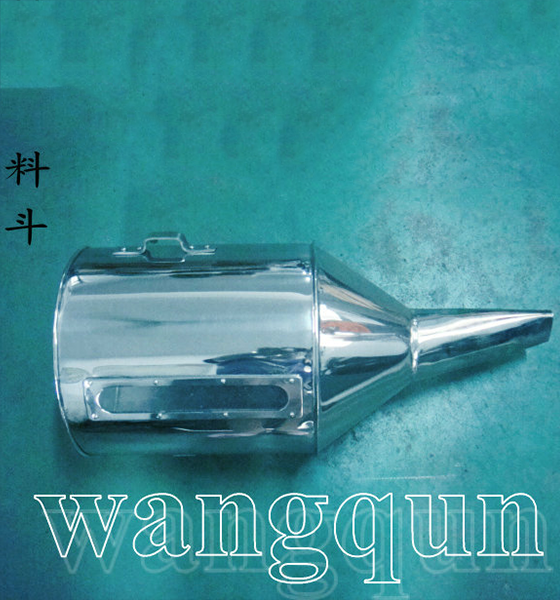

Tablet Press Hopper: Comprehensive Guide for Applications, Inspection, Maintenance, and Advantages

Introduction to Tablet Press Hopper

The Tablet Press Hopper is an essential component in pharmaceutical Tablet press machines, designed to store and feed powdered or granulated material consistently into the tablet compression system. Constructed from high-quality stainless steel or durable alloy, the hopper ensures hygienic handling, smooth material flow, and precise tablet weight control.

By maintaining a steady material feed, the tablet press hopper helps achieve consistent tablet quality, reduced production downtime, and increased operational efficiency. It is widely used in pharmaceutical, chemical, and food industries, making it a critical accessory for high-efficiency tablet manufacturing.

Core Features and Advantages

Durable Construction – Made from corrosion-resistant stainless steel or high-strength alloys for long-term use.

Hygienic Design – Compliant with GMP standards, easy to clean and maintain.

Smooth Material Flow – Optimized design reduces clumping, ensures uniform tablet weight.

Compatibility – Fits multiple tablet press models for seamless integration.

Reduced Downtime – Robust construction minimizes risk of damage during operation.

Operational Safety – Designed to meet industrial safety requirements.

Application Cases

The tablet press hopper is used in a variety of industrial settings:

Pharmaceutical Industry

Food Industry

Handling powdered nutritional supplements, vitamins, and confectionery tablets.

Ensuring uniform compression for quality control and production efficiency.

Chemical Industry

Research and Development

Product Specification Table

| Parameter | Specification | Notes |

|---|

| Material | Stainless Steel 304 / High-Strength Alloy | Corrosion-resistant, food-grade |

| Capacity | 5–25 liters | Depending on tablet press model |

| Weight | 2–6 kg | Varies with material and size |

| Diameter | 150–350 mm | Compatible with standard hopper mounts |

| Height | 200–450 mm | Adjustable for machine models |

| Surface Finish | Ra ≤ 1.6 μm | Smooth surface for optimal flow |

| Operating Temperature | 5–40°C | Avoid extreme heat or cold |

These specifications ensure smooth material flow, durability, and long-term reliability for high-volume tablet production.

Inspection Standards

Regular inspection ensures safe operation and consistent production quality.

Visual Inspection

Check for dents, cracks, or deformation.

Ensure welds and joints are intact and corrosion-free.

Dimensional Verification

Surface Quality Check

Inspect for scratches, rough surfaces, or irregularities.

Ensure compliance with GMP or FDA hygiene standards.

Functionality Test

Maintenance Recommendations

Daily Maintenance

Inspect hopper for visible damage or contamination.

Wipe interior and exterior surfaces with a clean, dry cloth.

Weekly Maintenance

Monthly Maintenance

Examine for wear, corrosion, or surface degradation.

Inspect alignment with tablet press feed mechanism.

Annual Maintenance

Conduct a full inspection of hopper, mounting system, and sealing components.

Replace any worn or damaged hoppers to maintain consistent tablet quality.

Core Advantages of Tablet Press Hopper

Improves Production Efficiency – Ensures continuous material feed, reducing machine downtime.

Enhances Tablet Quality – Smooth and controlled material flow supports consistent tablet weight and thickness.

Durable and Reliable – Long-lasting construction minimizes replacement frequency.

Hygienic and Safe – Compliant with food and pharmaceutical industry standards.

Versatile Application – Suitable for multiple tablet press models and industrial environments.

Conclusion

The Tablet Press Hopper is a critical component that ensures safe, efficient, and reliable tablet production. By adhering to proper inspection standards, maintenance routines, and operational practices, manufacturers can achieve high-quality tablets, reduced downtime, and enhanced productivity.

Investing in a high-quality, corrosion-resistant hopper allows for smooth material handling, operational efficiency, and long-term reliability, making it an essential accessory in pharmaceutical, chemical, and food tablet manufacturing.

Phone

Phone