Features:

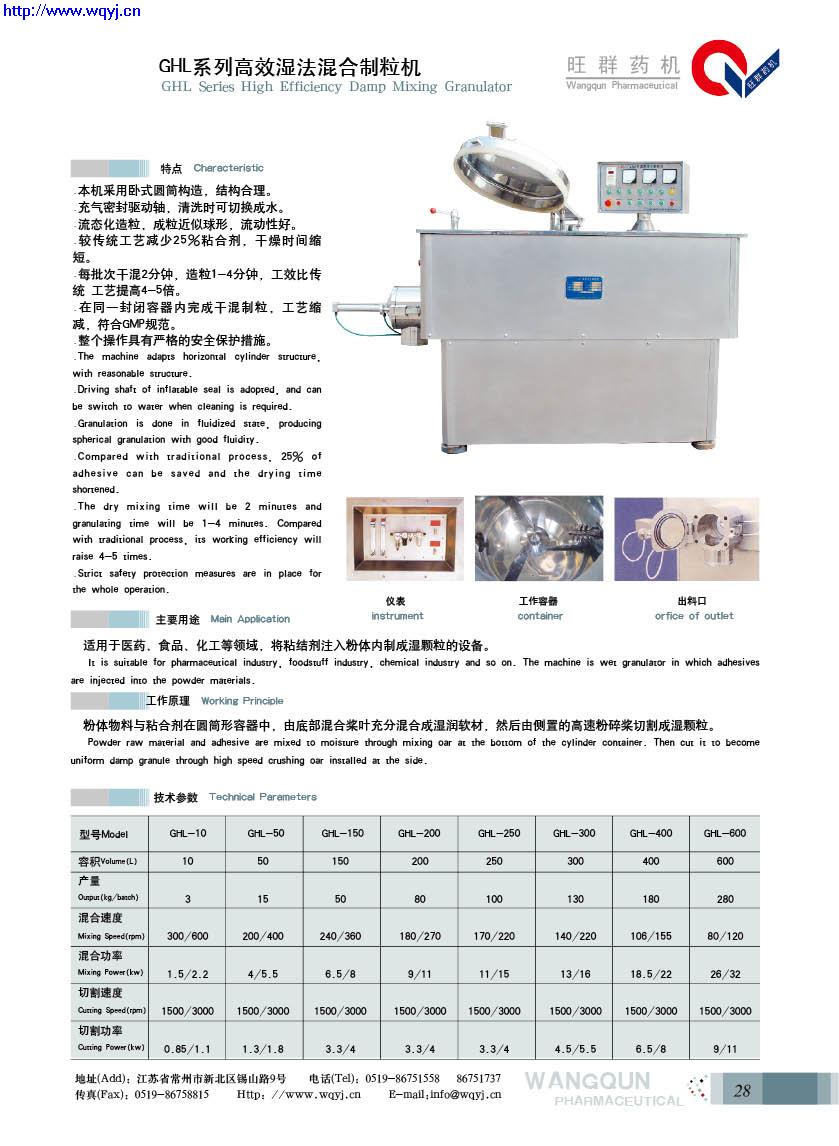

This machine adopts horizontal cylinder structure with reasonable structure.

Inflatable and sealed drive shaft, can be switched to water for cleaning.

The particles are fluidized and nearly spherical in shape with good fluidity.

Compared with traditional processes, it reduces 25% of adhesive and shortens drying time.

GHL Series High Efficiency Damp Mixing Granulator: Structure, Operation, and Specifications

Introduction

The GHL Series High Efficiency Damp Mixing Granulator is an advanced industrial solution designed for efficient wet granulation of powders. Widely used in pharmaceutical, chemical, and feed industries, it ensures uniform granule formation, optimal mixing efficiency, and high productivity.

Engineered with durable materials and precision components, the GHL Series granulator offers reliable performance, energy efficiency, and ease of operation, making it a preferred choice for large-scale granulation applications.

Structural Description

The GHL Series granulator is designed for stability, efficiency, and safety. Key structural components include:

Mixing Chamber – Constructed from stainless steel, designed to handle damp powders and prevent material adhesion.

Mixing Blades – High-strength, abrasion-resistant blades ensure thorough and uniform mixing of materials.

Drive System – Includes motor, gearbox, and shaft assembly to provide consistent rotational speed and torque.

Discharge System – Equipped with valve-controlled outlets for easy material extraction and minimal wastage.

Safety Guards – Protective covers and interlocks prevent operator injury during operation.

Control Panel – User-friendly interface for adjusting mixing speed, operation time, and monitoring system parameters.

The modular design allows for easy maintenance, cleaning, and part replacement, reducing downtime and operational costs.

Packaging Specifications

The GHL Series granulator is packaged to ensure safe transport and easy installation:

| Package Type | Material | Dimensions (L×W×H) | Weight |

|---|

| Standard Export Package | Wooden crate + protective film | Customized per machine size | 500–1500 kg |

| Internal Protection | Foam padding + shock absorbers | Fits internal components | Included |

| Accessories Package | Labeled boxes | Variable | 20–50 kg |

Each machine is carefully secured and labeled, with installation manuals and safety instructions included for smooth on-site assembly.

Operation Instructions

Pre-Operation Checks

Verify that the power supply matches machine requirements.

Inspect the mixing chamber and blades for obstructions, damage, or residue.

Ensure that all safety interlocks and protective covers are in place.

Confirm that the control panel and emergency stop button are functional.

Starting the Granulator

Open the feeding inlet and load raw material gradually.

Turn on the main power switch and set the desired mixing speed and operation time.

Monitor the material flow and blade rotation to ensure uniform mixing.

Adjust parameters as needed to achieve optimal granule size and moisture content.

During Operation

Observe temperature and torque readings to prevent overheating or overload.

Avoid exceeding the maximum material capacity of the mixing chamber.

Ensure continuous supervision during high-speed operation.

Shutdown Procedure

Stop feeding material and allow the granulator to complete the mixing cycle.

Open the discharge valve and remove granules carefully.

Turn off the motor and power supply.

Clean the mixing chamber, blades, and discharge system thoroughly.

Maintenance Guidelines

Regular maintenance ensures long-term performance and safety:

| Maintenance Task | Frequency | Description |

|---|

| Visual Inspection | Daily | Check blades, chamber, and discharge system for damage |

| Lubrication | Weekly | Apply recommended lubricant to motor and gearbox |

| Cleaning | After Each Operation | Remove residues to prevent contamination |

| Component Check | Monthly | Inspect bolts, screws, and safety interlocks |

| Full Servicing | Annually | Replace worn blades, seals, and bearings |

Proper maintenance reduces downtime, wear, and energy consumption, extending the machine’s operational life.

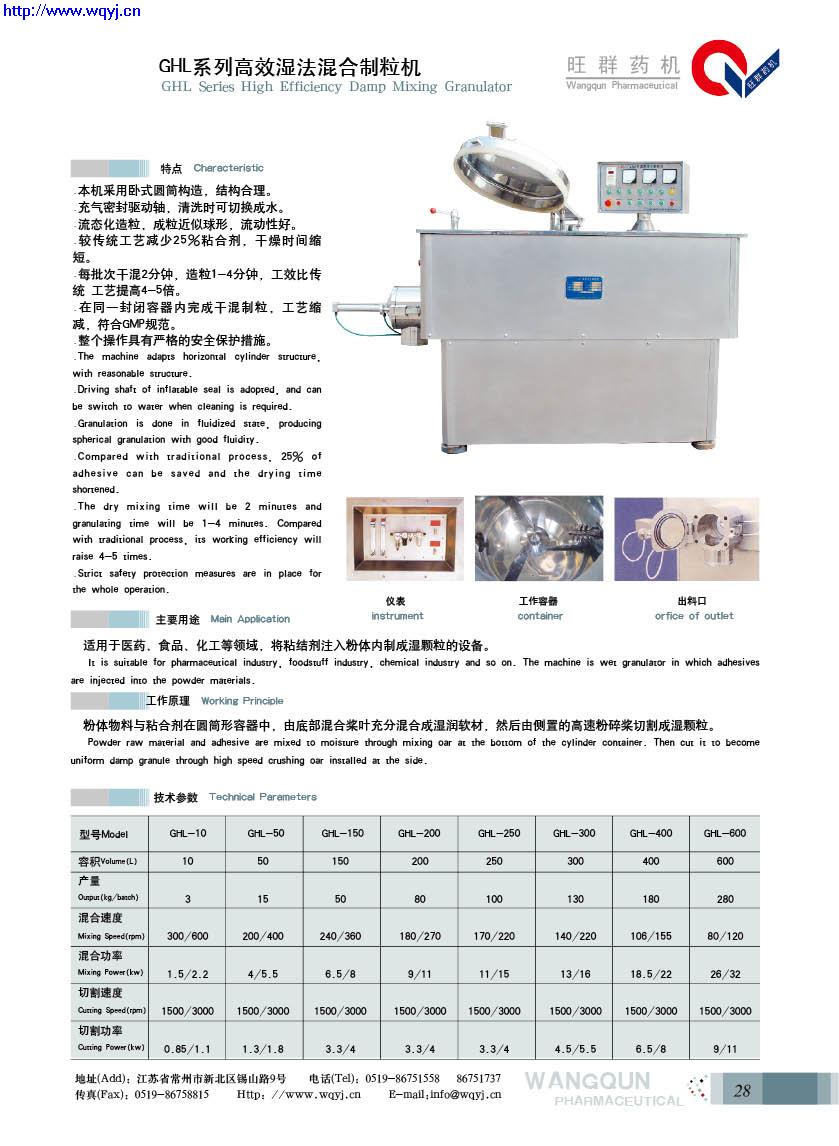

Product Parameters

| Model | Mixing Capacity (kg/batch) | Motor Power (kW) | Blade Speed (rpm) | Dimensions (mm) | Weight (kg) |

|---|

| GHL-200 | 50–200 | 7.5 | 40–60 | 1500×1000×1200 | 550 |

| GHL-500 | 200–500 | 15 | 35–55 | 2000×1200×1400 | 950 |

| GHL-1000 | 500–1000 | 22 | 30–50 | 2500×1500×1600 | 1450 |

These specifications allow flexible production planning and adaptation to different industrial requirements.

Advantages of GHL Series Granulator

High Efficiency – Achieves uniform granule size in shorter processing times.

Durable Construction – Stainless steel and abrasion-resistant components ensure long service life.

Energy Saving – Optimized motor and blade design reduce power consumption.

Easy Maintenance – Modular parts allow for quick cleaning and replacement.

Safety Compliance – Equipped with protective covers, interlocks, and emergency stop functions.

Versatile Application – Suitable for pharmaceutical, chemical, and feed granulation.

Applications

The GHL Series High Efficiency Damp Mixing Granulator is widely used for:

Pharmaceutical Industry – Wet granulation of tablets, capsules, and excipients.

Chemical Industry – Uniform granulation of powders and fertilizers.

Feed Industry – Production of animal feed pellets with consistent size.

Food Industry – Granulation of food additives, spices, and nutrient powders.

Troubleshooting Common Issues

| Problem | Possible Cause | Recommended Solution |

|---|

| Uneven granule size | Blade wear or improper speed | Replace blades or adjust speed |

| Material sticking to chamber | High moisture or residue buildup | Adjust moisture, clean chamber regularly |

| Excess vibration | Loose bolts or misaligned shaft | Tighten bolts, realign shaft |

| Motor overload | Excess material or jam | Reduce feed, check blade rotation |

Conclusion

The GHL Series High Efficiency Damp Mixing Granulator combines precision engineering, durable materials, and energy-efficient design to provide reliable and high-quality granulation across various industrial applications. With easy operation, comprehensive maintenance guidelines, and robust packaging, it is an ideal solution for manufacturers seeking consistent pellet and granule production, reduced downtime, and long-term cost savings.

Phone

Phone