rotary tablet press for Metal Forming Applications

Introduction

The rotary tablet press is a versatile and widely used machine in various industries, including pharmaceuticals, ceramics, and metallurgy. In metal forming applications, rotary tablet presses play a crucial role in producing high-density, uniform metal powder compacts that serve as precursors for sintering, forging, or other secondary processes. These machines offer precision, efficiency, and scalability, making them indispensable in modern powder metallurgy (PM) and advanced manufacturing.

This article explores the working principles, key components, advantages, and applications of rotary tablet presses in metal forming. Additionally, it discusses critical considerations for optimizing performance and future trends in the field.

Working Principle of Rotary Tablet Press

A rotary tablet press operates on a continuous rotary motion principle, where powder material is fed into dies and compressed between upper and lower punches to form tablets or compacts. The process involves several stages:

1. Feeding – Metal powder is gravity-fed or force-fed into the die cavities as the turret rotates.

2. Pre-compression – Some presses apply a preliminary compression to remove air and improve density uniformity.

3. Main Compression – The upper and lower punches exert high pressure to compact the powder into a solid tablet.

4. Ejection – The lower punch rises to eject the formed tablet from the die.

5. Take-off – The tablet is removed from the press via a discharge chute or conveyor.

The entire process is automated, ensuring high throughput and consistency.

Key Components of a Rotary Tablet Press

1. Turret

The turret is a rotating disc that holds multiple dies and punch sets. Its speed determines the production rate.

2. Punches (Upper and Lower)

Punches apply compressive force to the powder. They are made from high-strength tool steel or carbide to withstand wear.

3. Die Table

The die table contains cavities where powder is filled and compressed. Dies must be precisely machined to ensure dimensional accuracy.

4. Feeding System

A hopper and feed frame ensure uniform powder distribution into the dies. Force feeders may be used for poorly flowing powders.

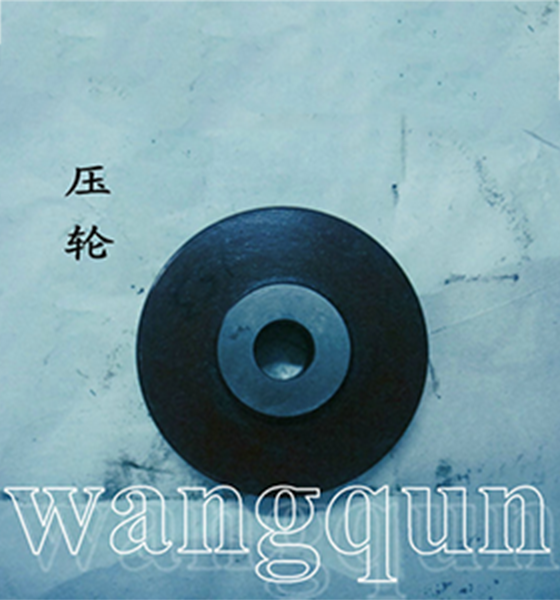

5. Compression Rollers

Stationary rollers apply pressure to the punches as they pass beneath them. The compression force is adjustable.

6. Ejection Cam

Guides the lower punch upward to eject the tablet after compression.

7. Control System

Modern presses feature PLC or CNC controls for monitoring pressure, speed, and tablet weight.

Advantages of Rotary Tablet Presses in Metal Forming

1. High Production Rates

Rotary presses can produce thousands of tablets per hour, making them ideal for mass production.

2. Uniform Density and Strength

The controlled compression process ensures consistent density, reducing defects in sintered parts.

3. Flexibility in Shape and Size

Different punch and die configurations allow for various tablet geometries, including multi-layer compacts.

4. Automation and Precision

Automated weight control and force monitoring minimize variations, improving product quality.

5. Reduced Material Waste

Efficient powder feeding and compaction minimize material loss compared to other forming methods.

Applications in Metal Forming

1. Powder Metallurgy (PM) Components

Rotary presses produce green compacts for sintering into gears, bearings, and structural parts.

2. Metal Injection Molding (MIM) Feedstock

Pre-compacted pellets serve as feedstock for injection molding processes.

3. Refractory Metals and Carbides

Tungsten, molybdenum, and cemented carbide powders are pressed into preforms for sintering.

4. Additive Manufacturing (AM) Precursors

Metal powder tablets can be used in binder jetting or other AM processes.

5. Magnetic and Electronic Components

Soft magnetic composites (SMCs) and conductive pastes are compacted into functional parts.

Critical Considerations for Optimization

1. Powder Characteristics

- Flowability – Poor flow can cause inconsistent filling; additives or force feeders may be needed.

- Particle Size Distribution – Fine powders may require higher compaction pressures.

- Lubrication – Internal or external lubricants reduce friction and ejection forces.

2. Tooling Design

- Punch and Die Material – Hardened steel or carbide extends tool life.

- Die Wall Friction – Polished dies minimize sticking and wear.

3. Process Parameters

- Compression Force – Must be optimized to avoid cracking or insufficient density.

- Turret Speed – Higher speeds may reduce dwell time, affecting tablet integrity.

4. Quality Control

- Weight and Thickness Monitoring – Ensures uniformity.

- Density Testing – Critical for sintered part performance.

Future Trends

1. Smart Presses with AI Integration – Predictive maintenance and real-time process adjustments.

2. Multi-layer and Gradient Compacts – Advanced tooling for functionally graded materials.

3. Eco-friendly Processing – Reduced energy consumption and recyclable lubricants.

4. Hybrid Manufacturing – Combining pressing with additive techniques for complex geometries.

Conclusion

Rotary tablet presses are essential for high-efficiency metal powder compaction, offering precision, scalability, and versatility. Their applications span from traditional powder metallurgy to emerging additive manufacturing technologies. By optimizing powder properties, tooling, and process parameters, manufacturers can achieve superior product quality and cost-effectiveness. Future advancements in automation and material science will further expand their capabilities in metal forming industries.

This comprehensive overview highlights the critical role of rotary tablet presses in modern manufacturing, emphasizing their advantages, challenges, and evolving trends.

Phone

Phone

Comment

(0)